Blow-patcher

Ideal for Localized Damage to a Road Surface

The Blow-Patcher from schäfer-technic is a state-of-the-art machine that meets the technical requirements for practical on-site operation. By using tried-and-tested components and metering units the Blow-Patcher achieves consistently accurate production of the asphalt mix. Special materials are used which minimize wear and maintenance, thereby safeguarding the machine‘s readiness for deployment. In the design phase plenty of thought went into making sure that the machine would be easy to use.

To increase the safety of the operator, the extention arm with mixing head will be installed in front of the truck. Also a handling with joy-stick is possible. The operator is able to steer and operate the arm with joy-stick directly from the driver‘s cab.

The Blow-Patcher method of road repair represents an affordable solution in high quality. A constant and reproduceable mixing quality is guaranteed by the further development of machine technology and metering unit. It can be used in a variety of ways with any type of asphalt paving, is efficient because it delivers the mix accurately to the point of failure, and is economical in its use of material and resources. The repaired section of road can be opened up to traffic again immediately.

This method is suitable for repairing damage to asphalt surfaces including potholes, frost heave, sinking, eruptions at the edge of the road surface, thinning of the surface layer and fine cracks. It can be used to repair damage sustainably, thereby maintaining safety for road traffic and renovating the road surface. The road surface can also be prepared for further surfacing work.

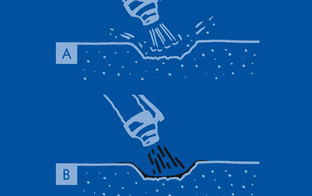

A - Blow clean

Dust and dirt is removed from the damaged area with compressed air or additionally with a water-spray attachment.

B - Spray with binder

The cleaned surface is evenly sprayed with a bitumen emulsion to create the best possible bond with the base surface.

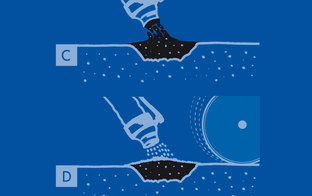

C - Fill with a mix of emulsion/chippings

Bitumen emulsion and twice crushed and screened chippings is mixed in the mixer head and delivered into the pothole using compressed air. With larger holes, 4/8 or 6/10 chippings are used in the deeper section, and towards the surface 2/4 chippings are used.

D - Grit spreading

To prevent the chippings adhering to vehicle tires once the road is re-opened to traffic, fine chippings 2/4 are sprinkled on the repaired surface.

Compaction - Right after repair of the damaged area roll and compaction with an asphalt compactor - Reduction of loose chippings.

Model Overview

A - Mountable or permanently mounted

H - Trailer

F* - Front patching

H* - Rear patching

FH* - Front patching with joy-stick

Technical Specifications

| Type | Capacity chippings m³ | Bitumen emulsion (l) | Water (l) | Weight (kg) | Dimensions L x W x H mm | Operation |

|---|---|---|---|---|---|---|

| A-3 | 3,0 | 1.200 | 250 | 2.900 | 4.700 x 2.230 x 1.730 | F* / H* |

| A-4 | 4,0 | 1.200 / 1.700 | 250 / 500 | 3.100 | 4.700 x 2.230 x 1.780 | F* / H* |

| A-6 | 6,0 | 1.200 / 1.700 | 250 / 500 | 3.300 | 4.850 x 2.230 x 2.000 | F* / H* |

| H | 0,5 | 1.200 | 250 | 5.500 | 5.300 x 2.350 x 2.200 | H* |

| HT-P | 4,5 | 1.200 | 500 | 4.650 | 6.750 x 2.250 x 2.700 | H* |

| HT-D | 4,5 | 1.200 | 500 | 4.650 | 6.750 x 2.250 x 2.700 | H* |

| FAH-4 | 4,0 | 1.700 | 250 / 500 | 4.920 | 6.750 x 2.250 x 2.700 | FH* |

| FAH-6 | 6,0 | 1.700 | 250 / 500 | 5.200 | 6.750 x 2.250 x 2.800 | FH* |